Large-Scale Multisegment Fluidic Continuum Arms with Extended

Stiffness Modulation and Methods of Optimized AI/ML Models in their Identification

To research the large-scale continuum arms with intrinsic structure using technologically advanced and commercially available fluidic actuators for industrial scenario to bring the idea of affordable and inherently safe continuum arms closer to real-world applications together with the application of advanced and optimized AI/ML models for addressing the issues of complex phenomena description taking place in such arms.

Meet the experts driving innovation in OptimAI

Based on the current situation, the following challenges have been identified:

Data-driven models present powerful tool for modeling both kinematics and dynamics of SCAs but the design of these models, especially in their deep architecture form is challenging and typically not subject to optimization.

Based on the existing challenges, OptimAI-ContiFEx will address the following:

Optimizing the RNNs models hyperparameters and structure using SOTA bio-inspired algorithms

The project’s expected results focus on construction and modeling. Current soft continuum arms often use novel, custom actuators with impressive properties but lack standardization of commercially available products and are mostly suited for lab environments. These actuators also typically offer low force output, limiting their industrial use. Fluidic muscles, in contrast, are powerful variable stiffness actuators that are affordable, robust, and commercially available. Though not entirely soft (due to metal caps) and designed as linear actuators, their slim profile (5–10 mm diameter) and high force/weight ratio make them promising. Their bending capability, arising from rubber tubing, remains underexplored. Simultaneous activation/deactivation of muscle pairs or triads could offer effective stiffness modulation and improve task-space positioning.

To enhance stiffness control independently of actuation, we propose integrating a granular jamming backbone. For system identification, textile-based soft sensors will be employed to measure actuator lengths, offering a cost-effective alternative to wire encoders, especially in large-scale systems.

While finite element models provide accurate representations, they are computationally intensive. Simpler models may miss critical effects like hysteresis or creep. Temporal data-driven methods such as recurrent neural networks present a compelling solution. We aim to optimize their architecture and hyperparameters using SOTA bio-inspired algorithms tailored to dynamic modeling of fluidic soft continuum arms.

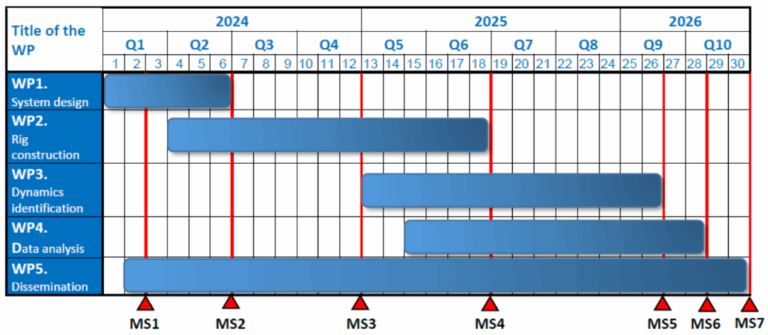

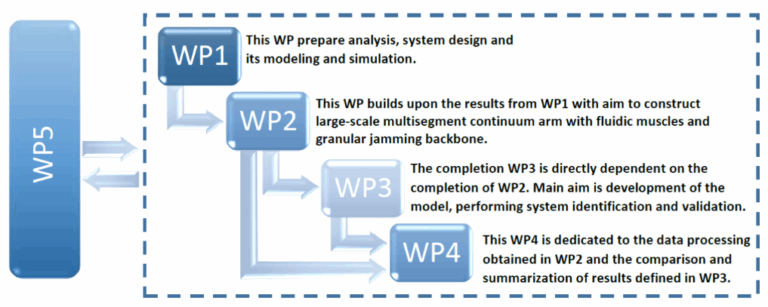

OptimAI-ContiFEx runs for a period of 30 months with a plan divided into five work packages:

WP1 is dedicated to system design and modeling, where systems are being designed and modeled.

WP2 focuses on the construction of a one-segment experimental test rig and its large-scale version with multiple segments.

The third work package includes tasks related to performing system dynamics identification using optimized RNN models and validating them.

WP4 and WP5 focus on final data analysis for performance evaluation and reporting, as well as dissemination and exploitation, respectively.

The implementation timetable for the work packages is shown using the Gantt diagram below.

The interconnection of the work packages is illustrated using the PERT diagram found beneath the Gantt chart.

The main objectives of WP1 will be as follows:

In accordance with the project’s specific objective 2 and 3, the objectives of this WP will be:

In accordance with the project’s specific objective 4, the objectives of this WP will be:

The main objectives of this work package will be:

In accordance with the chosen measures for maximizing impact, the objectives to develop in this WP will be:

Research and teaching laboratory based on an experimental SMART production system with installed technologies of advanced robotics, progressive production, digitization (digital twin, clouds), visual systems and RFID/IoT (product identification) , VR/AR and mixed reality, PLC control. This lab will be used for optimization of AI/ML models using SOTA algorithms.

A research laboratory equipped with measuring technology (universal and special measuring instruments) for research in the field of soft robotics and soft actuators (fluidic muscles, actuators based on shape memory alloys – SMA, polymer soft drives – IPMC, DEA, HASEL), manipulators based on PAMs (2-DOF, 3-DOF, multi-parallel connections) and automatic control systems (advanced control of machines and processes). This lab will be used for data processing and system identification.

Teaching and research laboratory of PLC systems for controlling machines and processes, IIoT and microcontrollers for collecting and processing data from sensors and solving simple control tasks, HMI/SCADA systems for visualization and monitoring, systems for optimizing production processes and corporate information. This lab will be used for the sensorization process and electronics component testing.

Research and teaching laboratory equipped with control systems, DAQs, electronic components, measuring instruments, conventional electric drives and actuators, compliant manipulator, a desktop industrial robot and power supplies for designing and real-time control of mechatronic systems. This lab will be used for the construction and testing of experimental rigs.